Posted in April 2017

First Test Prints

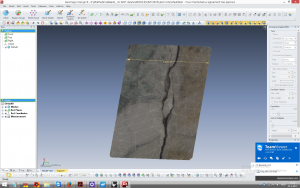

First test prints of the section under study have been produced at the CAMlab of TU Delft. A modified section was produced at a reduced scale (15x20cm) to study the form and appearance of the structural crack, currently present at the walls of the Hippolytuskerk, Middelstum.

Conversion of virtual models into printable files

In the following weeks, a portion of about 65×35 cm was made in high resolution, to test the formats with the 3D printer. A sliced portion of 15×15 cm high resolution were late made to generate the g-code and make sure that the prints could be eventually produced.

It was advised that:

Accordingly, the mesh was optimized in Geomagic. A reamining issue was to get the precise number of the measurement due to zoom issues in Geomagic and the rough corner to put the trim point.

– In this mesh processing, Geomagic design 5.1.0.0 was used. In this case, Geomagic design has no option to export to ZPR format.

The available formats are .xtl, .obj, .3ds, .wrl (VRML 1.0 file and VRML 97 File), .ptc, .pts, .ply, .asc, .dxf, .icf, .xdl, .mdl)

– It was agreed that for the workshop in future, a reduced number of triangle will be provided. But for the test prints (15×20), the scanning team prefered to deliver a higher quality to show the depth of the crack.

3D Scans of the Threatened Structure

On Tuesday, 21st of February, project members Valentin vanhecke and Miktha Farid conducted the first scans of the Church in Middelstum. As it was practically impossible to reach the required height with the scaffolds, the project members carried out the required scans with the laserscanner from as close as possible, with a resolution of around 0.5 mm and with the highest quality available. Many pictures were captured in order to provide the best possible colours. 3D virtual models were developed through combining photogrammetry with laser scanning.

Recent Comments