Posted in July 2017

Design Studio: The seam as a pattern

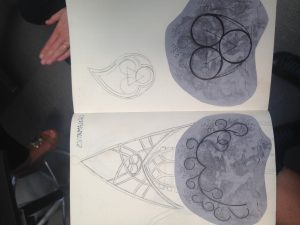

Project member Peter Koorstra, together with his students of the Form and Modelling design studio are working on understanding the seam as pattern. The student work aims at coming up with innovative solutions to replace damaged architectural heritage. It looks into the possibilities of combining different 3D printed panels to replace the vault at the Hippolytuskerk. The design studio highlights the issues of seams, and how can the seams be incorporated in the new designs.

Visit to the Cultural Heritage Agency of the Netherlands (RCE)

On the 9th of May, project members: Carola Hein, Angela Dellebeke and John Hanna visited the Heritage Agency of the Netherlands in Amersfoort.

In addition to collecting archival material of the church’s history and previous restorations,the project team discussed the updates and intended outcomes of the Hippolytuskerk project during their meeting with RCE experts and specialists from the domains of architectural heritage and paintings restoration.

Possibilities for producing the coloured surface of the vault in the Hippolytuskerk

On the 24th of April, 2017 proposals were made for the surface of the 3D printed structure:

- To add a thin 3D printed layer with microstructures, and final colours (maximum curvature/thickness of 5 cm) – which is added on a flat surface of a solid 3D structure, to reduce the costs.

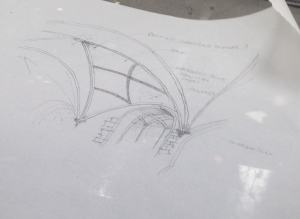

- Alternatively, the thin 3D printed surface, can be added to a spider-like structure, instead of a solid structure. This kind of structure could in future also be used in architectural heritage to fill e.g. holes, or missing parts as an alternative to Styrofoam, as illustrated in the image below.

- To print a coloured 3D model. However, the colour will have a plastic looking nature, as the technology does not provide an inkjet quality yet.

- To print the final colors and textures on a thin foil layer (50 microns) and fix it over the solid 3D structure, which in this case will have all the microstructures, and grains. The foil should be flexible and soft enough to stretch over the 3D structure.

Recent Comments